MANCHESTER, NH — In response to the COVID-19 coronavirus pandemic, makerspaces across the state have mobilized an effort to manufacture protective face shields for health care workers, Roy Schlieben, executive director of MAxT Makerspace in Peterborough, said on Monday.

“We decided to look into it about two weeks ago and within three days we were printing stuff and we were in contact with the other makerspaces and got tied into the other things going on in the state,” Schlieben said. “Our members are also working on fabric masks.”

Schlieben said they started working on the idea about two weeks ago. Everyone was looking for a way to help when they realized they could use the makerspace’s 3D printers and laser cutter to make face shields.

Schlieben said he soon learned that other makerspaces in the state — including Manchester, Nashua and Portsmouth — had the same thought.

The makerspaces started coordinating their efforts through the app “Slack.”

“The Slack makerspace network was formed over the past year and this is really the first time we have collaborated statewide,” he said. “This is one area where we can really help.”

So far the effort has only cost Schlieben about $80 out of pocket buying supplies. A generous donor has bought other supplies and a large donation of plastic made to the makerspace in Nashua was shared with MAxT Makerspace.

“One of the makerspaces in Nashua got a big donation of plastic. … So they have given us a boatload of plastic to use so we are slicing that on our laser cutter.”

“The groups in Nashua and in Manchester had already talked to the hospitals and showed them different designs and vetted them out,” Schlieben said.

Over two days the Peterborough makerspace completed 150 of these face shields, which is set to go to Catholic Medical Center in Manchester.

Schlieben has since supplied some samples to Monadnock Community Hospital in Peterborough and they are now working on an order specific to that hospital.

“We’re gathering materials and we’re hoping to complete about 1,000 by next week,” he said.

The Peterborough operation has about 15 volunteers, most of whom were already members of the makerspace. Schlieben said he put out the call for volunteers via an email blast to makerspace members. Some volunteers have had to be trained on the 3D printer, but it has been worth it, Schlieben said.

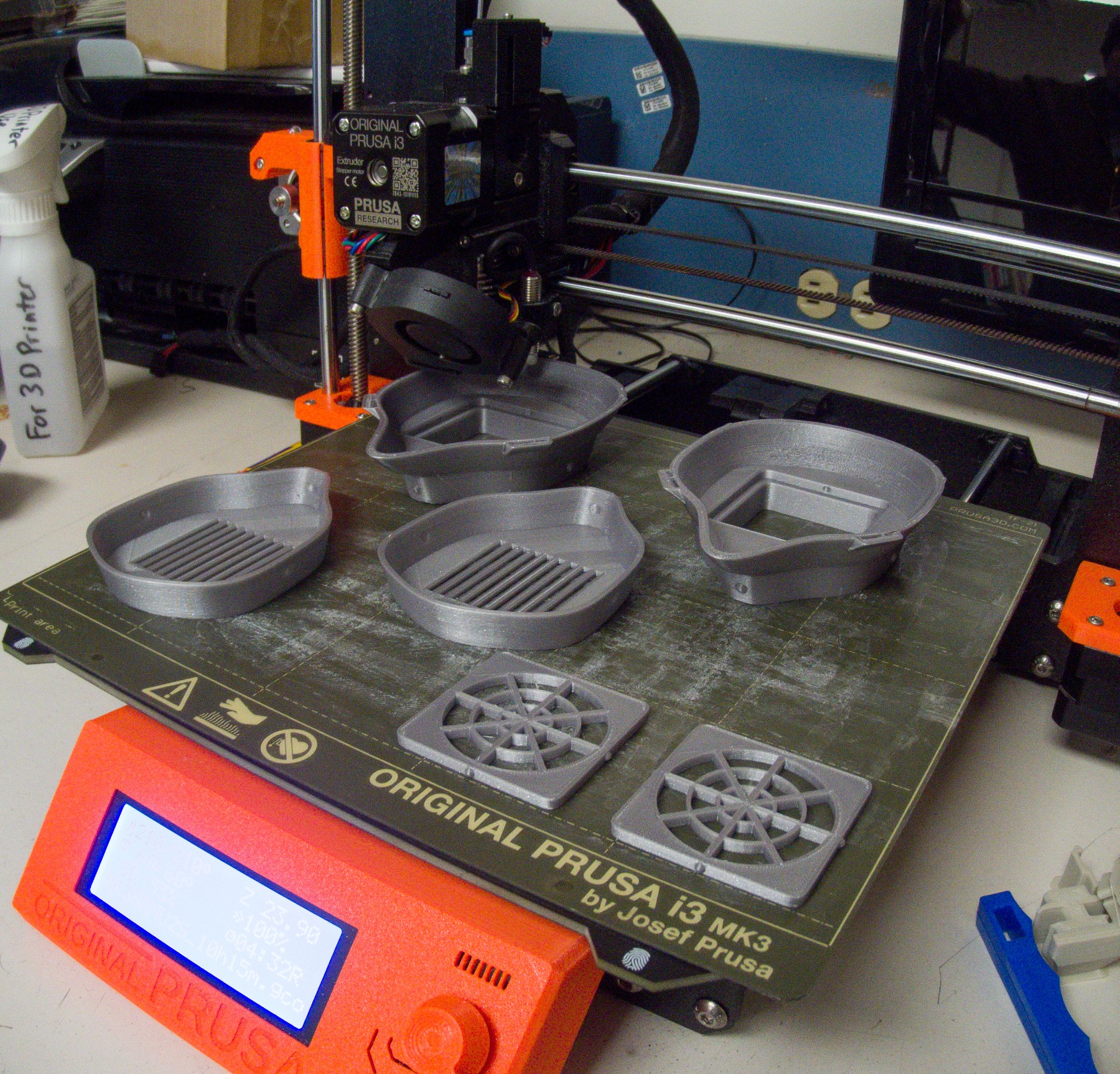

“We have a couple 3D printers at the makerspace running 24/7 now printing out parts,” he said. “Some people working at home are printing out parts.”

Volunteers are still welcome to join the effort, Schlieben said.

“I’m also involving anybody in the community around us if they have a home 3D printer they can start printing off parts,” he said. “The slowest part is printing, so the more people printing the better.”

Materials needed to make the face shields include spools of filament for the parts made on the 3D printers and plastic.

“We’ve got a good community that has sort of rallied to this cause and sort of helped out as we have gone along,” he said.

To keep the social distancing guidelines volunteers are working alone and asked to wash their hands as much as possible.

“We’re only allowing one person at a time to work in the makerspace. We have gloves for people to wear,” he said. “If people have masks that’s encouraged, wash your hands before you come in.”

The assembly of the face shields takes place at the makerspace.

“Most of the people are making the parts at home and bringing them to the makerspace and they can be assembled at the makerspace,” Schlieben said.

The project should be sustainable for about month, he said.

“As long as we are able to buy and get materials we can go for the next month or so,” Schlieben said. “As long as people still want the shields and we are ready to make them.”

Volunteering is not a heavy commitment, he said, some people help for a few hours others a full day. It is up to the volunteer.

“I think the biggest challenge is coordinating volunteers virtually and providing detailed instructions and problem-solving. Particularly with people who are not familiar with 3D printing and laser cutting,” he said. “Sometimes volunteers who jump at the chance need a little hand-holding.”

Once the local and statewide need is met these shields could be shipped anywhere, he said. “If we have a surplus these can go anywhere.”

Schlieben said they are using instructions from Prusa to make the protective face shields, which can be found online at https://www.prusaprinters.org/prints/25857-prusa-protective-face-shield-rc2.

To get involved contact your local makerspace. If you are in the Peterborough area you can reach Schlieben at Roy@maxtmakerspace.org.

These articles are being shared by partners in The Granite State News Collaborative. For more information visit collaborativenh.org.

These articles are being shared by partners in The Granite State News Collaborative. For more information visit collaborativenh.org.